Products

Discover our range of valves built to the highest industry standards. We partner with top manufacturers and ensure rigorous quality checks to provide products you can trust.

Select Product Category

Field Instruments

Fire & Gas Detectors & Devices

Mannual & Actuated Valves

Process Valves

Speciality Items

Select Products

Process with Flowmeters

CORIOLIS FLOWMETER

Coriolis flowmeters are a type of mass flow meter that measures the mass flow rate of fluids by utilizing the Coriolis effect.

This technology provides highly accurate and reliable flow measurements for a wide range of fluids, including liquids, gases, and slurries

ULTRASONIC FLOWMETER

Ultrasonic flowmeters are sophisticated instruments that measure the flow rate of fluids within a pipe by utilizing the principles of sound wave propagation.

MAGNETIC FLOWMETER

Magnetic flowmeters, also known as electromagnetic flowmeters or magmeters, are devices used to measure the volumetric flow rate of conductive liquids. They operate on the principle of electromagnetic induction, where a voltage is induced in a moving conductor within a magnetic field.

Process Transmitters

Pressure Transmitter

Pressure transmitters are essential devices used to measure pressure and convert it into an electrical signal, typically 4-20 mA. This analog signal can then be used to monitor, control, and record pressure in various industrial processes.

Temp. Transmitter

Temperature transmitters are essential instruments used to measure temperature and convert the signal into a standardized electrical output, typically 4-20 mA. These transmitters are widely used in industries like oil and gas, chemical processing, manufacturing, and food processing to monitor and control temperature.

Differential Pressure Transmitter

Differential Pressure (DP) transmitters are instruments used to measure the pressure difference between two points in a system.

DP Type Flowmeter

DP flowmeters, also known as orifice meters, are widely used devices for measuring fluid flow rate within pipes. They operate based on the principle of Bernoulli’s equation, which states that as the velocity of a fluid increases, its pressure decreases.

DP Type Level Transmitter

Differential Pressure (DP) Level Transmitters are widely used instruments for accurately measuring the level of liquids in tanks, vessels, and other containers. They work by measuring the pressure difference between two points.

GWR Level Transmitter

GWR level transmitters utilize electromagnetic waves to accurately measure the level of various materials within tanks, vessels, and other containers.

Radar Non-contact Level Transmitter

Radar non-contact level transmitters utilize electromagnetic waves to accurately measure the level of liquids and solids within tanks, vessels, and other containers. Unlike traditional methods that involve physical contact with the material, radar transmitters operate non-intrusively, offering numerous advantages.

Magnetoistructive Level Transmitter

Magnetostrictive level transmitters are sophisticated devices used for precise measurement of liquid levels in various industrial applications. They offer high accuracy, reliability, and versatility, making them a popular choice in many industries.

Process Gauges

Pressure Gauges

A pressure gauge is a mechanical device used to measure fluid pressure. It consists of a pressure-sensing element, a mechanism to translate the pressure into a mechanical movement, and a dial to display the pressure reading.

Temperature Gauges

A temperature gauge is a device used to measure and display temperature. It consists of a temperature sensor, a mechanism to translate the temperature into a mechanical movement, and a dial to display the temperature reading.

Sight Flow Glass

Flow gauges are instruments used to measure and indicate the rate at which a fluid (liquid or gas) is flowing through a pipe or channel. They are essential tools in various industries for monitoring, controlling, and optimizing processes.

Level gauges

Magnetic Level Gauge

Flow gauges are instruments used to measure and indicate the rate at which a fluid (liquid or gas) is flowing through a pipe or channel. They are essential tools in various industries for monitoring, controlling, and optimizing processes.

Reflex Level Gauge

Reflex level gauges are a type of sight glass used to visually indicate the level of a liquid within a vessel or tank. Unlike transparent gauges, which allow you to see directly through the liquid, reflex gauges utilize a unique optical principle to provide a clear and distinct level indication.

Transparent level Gauge

Transparent level gauges, also known as sight glasses, are simple and reliable devices used to visually monitor the level of liquids within a vessel or tank. They offer a direct and immediate indication of the fluid level, making them a valuable tool in various industrial applications.

Select Products

Analog Detectors

Flame Detector

Flame detectors are crucial safety devices in the oil and gas industry, where the risk of fire and explosion is ever-present.

These devices continuously monitor for the presence of flames, providing early warning and enabling rapid response to potential hazards.

Toxic Gas Detector

Toxic gas detectors are critical safety devices that continuously monitor the air for the presence of hazardous gases. These devices provide early warning of gas leaks, allowing for prompt evacuation and corrective action, thus minimizing the risk of injury and property damage.

Hydrocarbon Gas Detector

Hydrocarbon gases, such as methane, ethane, and propane, are widely used in the oil and gas industry. However, they also pose significant safety hazards due to their flammability and potential for explosions. To mitigate these risks, hydrocarbon gas detectors play a crucial role in ensuring the safety of personnel and the environment.

Open Path Gas Detector

Open path gas detectors are advanced safety systems designed to monitor for the presence of hazardous gases over a specific distance, typically across an open area. Unlike point detectors that measure gas concentration at a single location, open path detectors create a virtual “wall” of detection, providing continuous monitoring across a wider area.

F&G Signaling Devices

Beacons

Beacons, small electronic devices that transmit signals via Bluetooth or other wireless technologies, are finding increasing applications in the oil and gas industry. They offer a range of benefits for enhancing safety, improving operational efficiency, and streamlining workflows.

Sounders

Sounders are essential safety devices in the oil and gas industry, providing audible warnings to alert personnel of potential hazards. These devices play a crucial role in ensuring worker safety and minimizing the risk of accidents.

Manual call Points

Manual call points are devices that, when activated, send a signal to the fire alarm control panel, initiating an alarm and triggering emergency response procedures.

They typically consist of a cover that, when broken, activates a switch within the device.

Select Products

Manual valves

Ball Valve

A ball valve is a valve that has a spherical “disc” or ball that has a bore cut through it. This valve works on rotational motion. Ball valves are quarter-turn valves, at 0 degrees the valve is in the fully open position and once the valve is actuated through 90 degrees the valve is fully closed.

Gate Valve

Manual gate valves are essential components in the oil and gas industry, providing reliable on/off control of fluid flow in pipelines and processing systems. Their simple design and robust construction make them a dependable choice for various applications.

Globe Valve

Manual globe valves are essential components in the oil and gas industry, prized for their ability to precisely regulate fluid flow. Unlike gate valves, which are primarily for on/off service, globe valves are designed for throttling and controlling the rate of flow. Their unique design makes them well-suited for applications where accurate flow management is crucial.

Check Valve

Manual globe valves are essential components in the oil and gas industry, prized for their ability to precisely regulate fluid flow. Unlike gate valves, which are primarily for on/off service, globe valves are designed for throttling and controlling the rate of flow. Their unique design makes them well-suited for applications where accurate flow management is crucial.

Choke Valve

Choke valves are variable orifice valves. They feature an adjustable flow passage, typically controlled by a stem or actuator, allowing for precise manipulation of the flow area. This adjustable orifice allows operators to control the flow rate and downstream pressure, even when upstream pressure fluctuates significantly.

Plug Valve

A plug valve is a quarter-turn rotary motion valve used to stop/start flow in a pipeline. This valve type uses a tapered or cylindrical plug to stop flow. There are two types of plug valves commonly used, lubricated and non-lubricated.

Actuated Valves

Pneumatic Shutdown & Blowdown valves

Open path gas detectors are advanced safety systems designed to monitor for the presence of hazardous gases over a specific distance, typically across an open area. Unlike point detectors that measure gas concentration at a single location, open path detectors create a virtual “wall” of detection, providing continuous monitoring across a wider area.

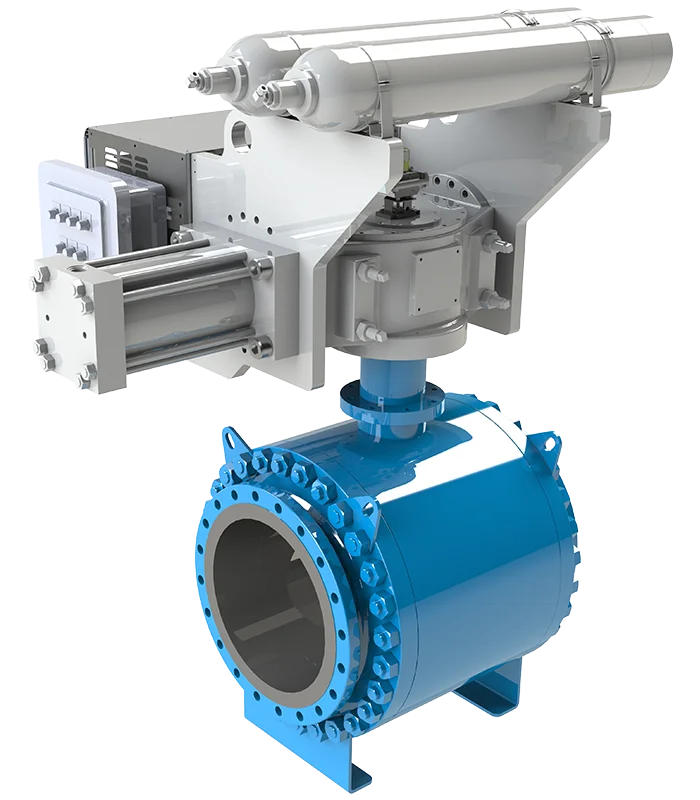

Pneumatic On-Off Valves

These valves utilize compressed air (pneumatic pressure) to actuate the valve mechanism, opening or closing the valve. A pneumatic actuator, connected to the valve, converts the air pressure into mechanical motion. These valves are typically used for on/off (open/closed) control and are not generally recommended for throttling or flow regulation.

Motor Operated Valves

Motor Operated Valves (MOVs) are valves that are actuated by an electric motor, providing automated control over fluid flow. These valves are widely used in various industries, including oil and gas, chemical processing, power generation, and water treatment.

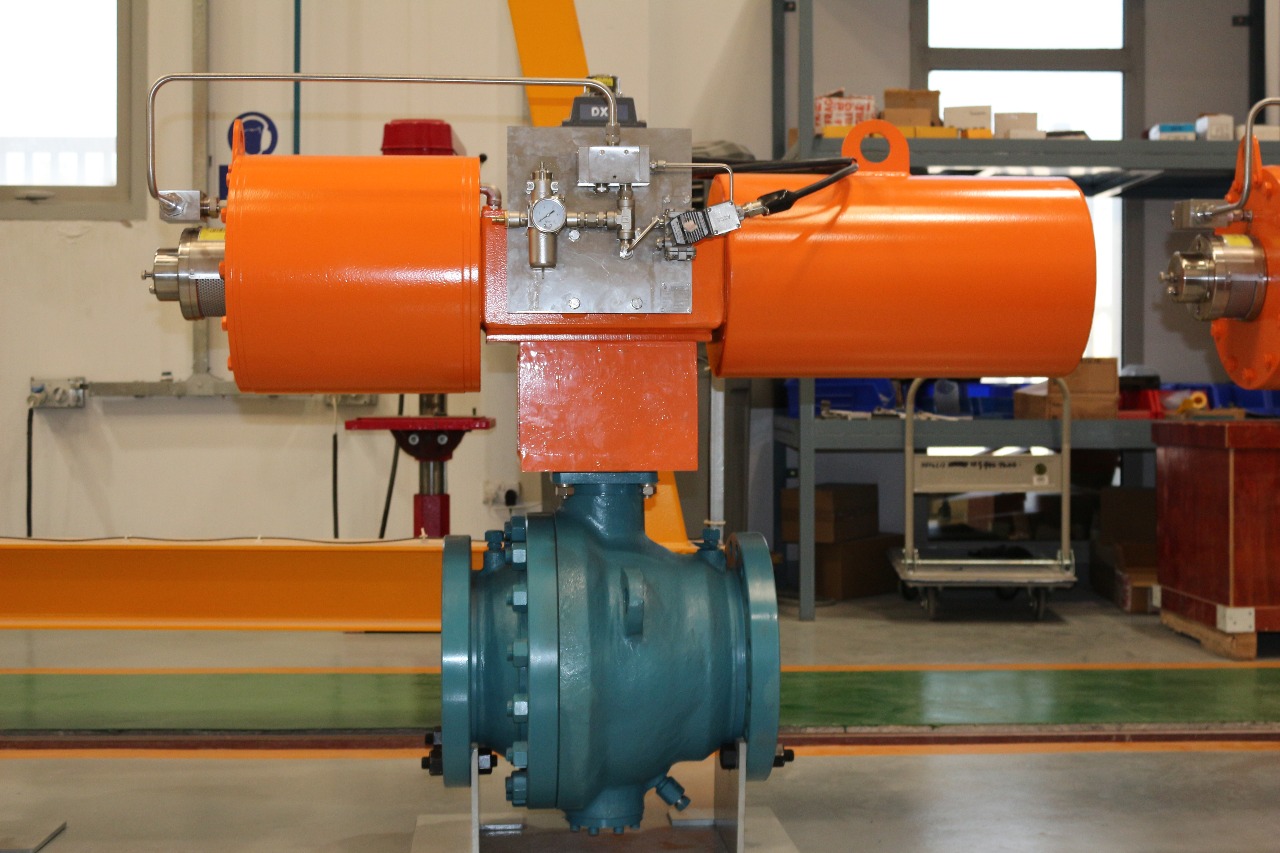

Electro-Hydraulic Valves

Electro-hydraulic valves utilize hydraulic power to actuate the valve mechanism, while electronic signals control the valve’s position and operation. This combination allows for precise control of flow rate, pressure, and direction, even in high-pressure and high-temperature environments.

Select Products

Process Valves

Control Valves

Control valves are automated valves used to control process variables such as flow rate, pressure, temperature, and level. They respond to signals from a control system (DCS, PLC) to automatically adjust the flow of fluids.

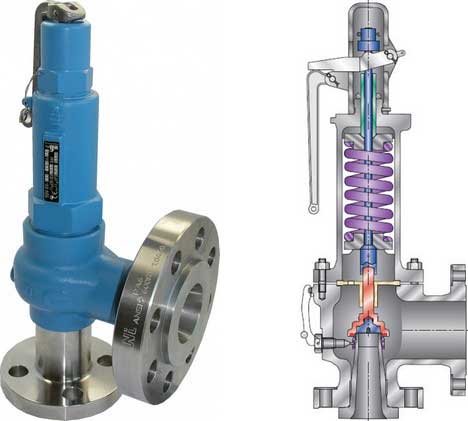

Pressure Relief Valves

Pressure relief valves (PRVs) are critical safety devices in the oil and gas industry, designed to protect equipment and personnel from overpressure conditions. These valves automatically release excess pressure, preventing catastrophic failures that can lead to injuries, environmental damage, and significant financial losses.

Pressure Regulated Valves

PRVs work by automatically adjusting the valve opening to restrict or allow flow, thereby controlling upstream pressure. They typically consist of a sensing element that detects pressure changes, a pilot mechanism that translates the pressure change into a mechanical movement, and a main valve that regulates the flow. No external power source is required for their operation; they are self-contained and operate based on the system pressure itself.

Pressure Vent & Relief Valves

Pressure vent and relief valves are critical safety devices in the oil and gas industry, designed to protect equipment and personnel from overpressure conditions. They act as the last line of defense, preventing catastrophic failures that can result in injuries, environmental damage, and significant financial losses. While often discussed together, vent and relief valves serve slightly different, though related, purposes.

Select Products

Speciality Items

Hose with Couplings

Hoses with couplings are vital components in the oil and gas industry, facilitating the safe and efficient transfer of fluids, gases, and other materials in various applications.

Camlock Coupling

Camlock couplings, also known as cam and groove couplings, are widely used in the oil and gas industry for their ability to provide quick and reliable connections for fluid transfer. Their simple design and ease of use make them a valuable asset in various applications.

Quick Release Coupling

Quick release couplings are mechanical devices designed to provide a fast and easy way to connect and disconnect hoses or pipes without the need for tools. They typically consist of two parts: a coupler (female end) and a nipple (male end). When connected, they form a secure and leak-tight seal, ensuring efficient fluid transfer.

Dry-Disconnect Coupling

Dry-disconnect couplings are invaluable in the oil and gas industry, offering a safe and efficient way to connect and disconnect fluid lines without spills or leaks. They are particularly crucial when handling hazardous or valuable fluids, where even small leaks can have significant consequences.

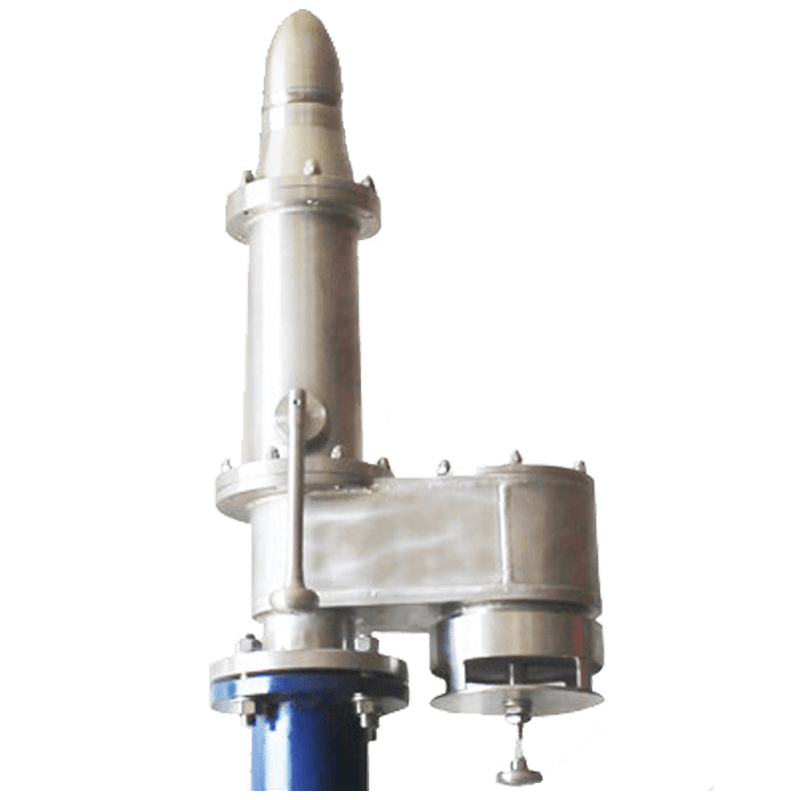

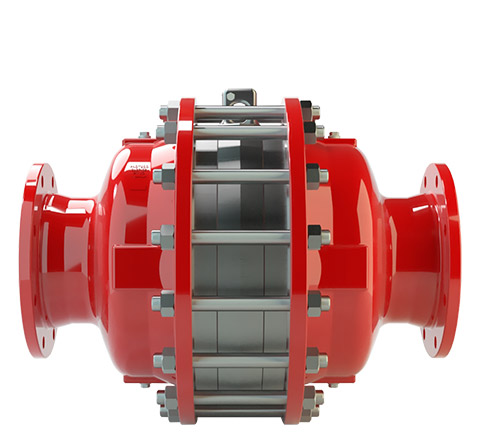

Flame Arrestor

Flame arrestors are critical safety devices used in the oil and gas industry to prevent the propagation of flames through pipelines or vessels containing flammable gases or vapors. They act as a barrier, stopping a flame from traveling and potentially causing a larger explosion.

Spark Arrestor

Spark arrestors are critical safety devices used in the oil and gas industry to prevent the emission of sparks from internal combustion engines, particularly diesel engines. These sparks can ignite flammable materials, posing a significant fire and explosion risk in environments where combustible gases or vapors may be present.

Corrossion Coupon

Corrosion coupons are a valuable tool for monitoring corrosion in the oil and gas industry. They can be used to assess the effectiveness of corrosion inhibitors, to identify areas of high corrosion, and to predict the remaining life of equipment.

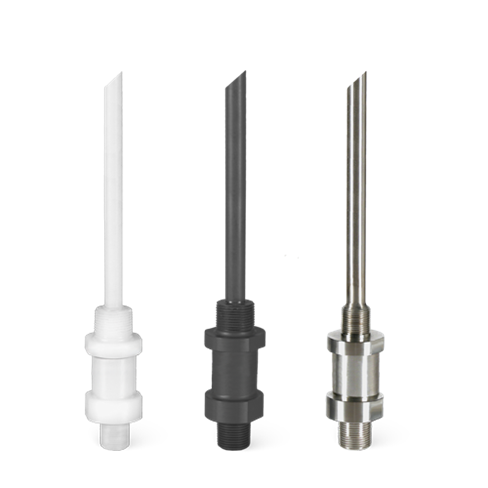

Injection Quills

Injection quills are typically installed through a fitting in the pipeline wall. They extend into the center of the flow stream, allowing for even distribution of the injected chemical. This prevents the chemical from channeling down the pipe wall and ensures it is effectively mixed with the process fluid.